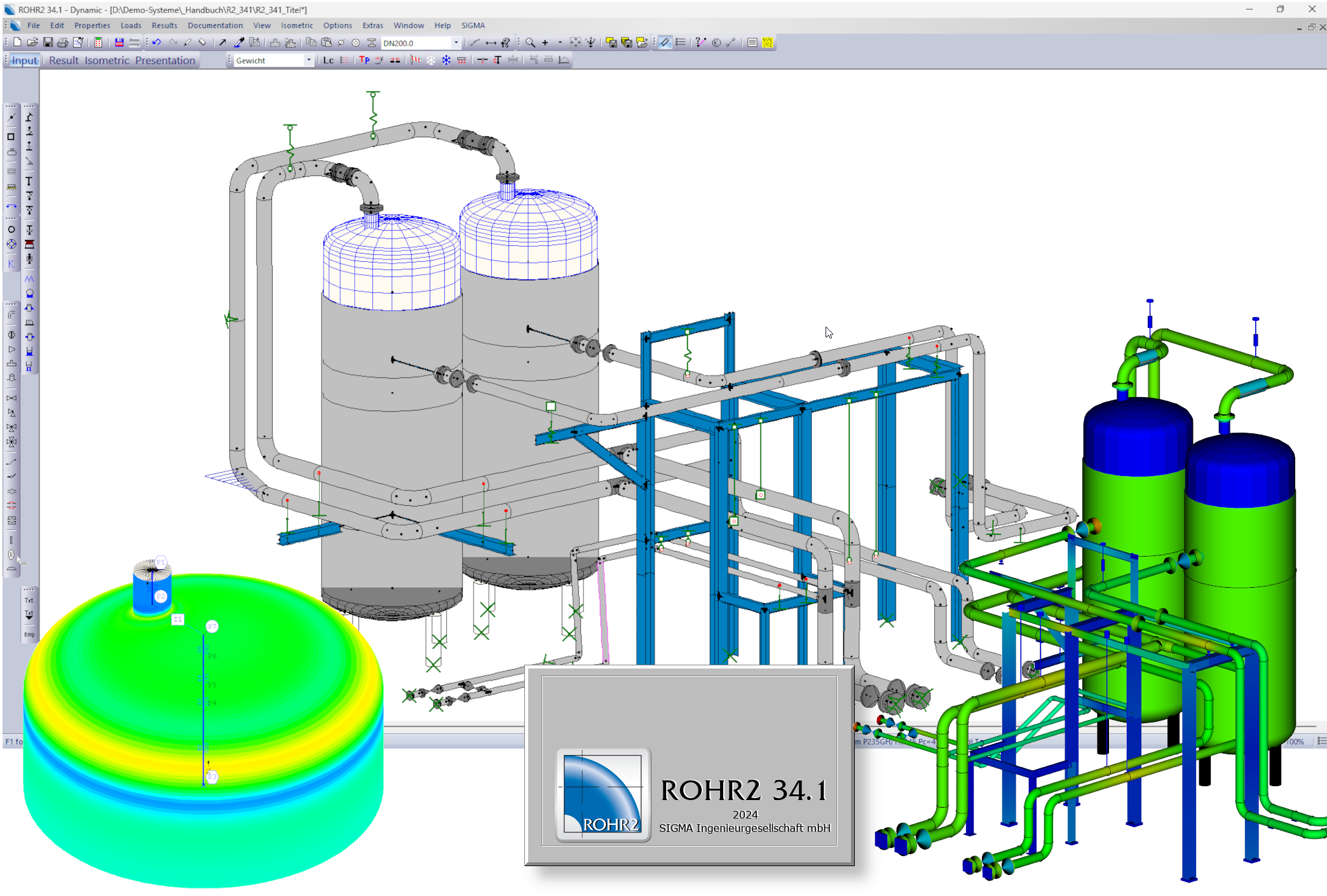

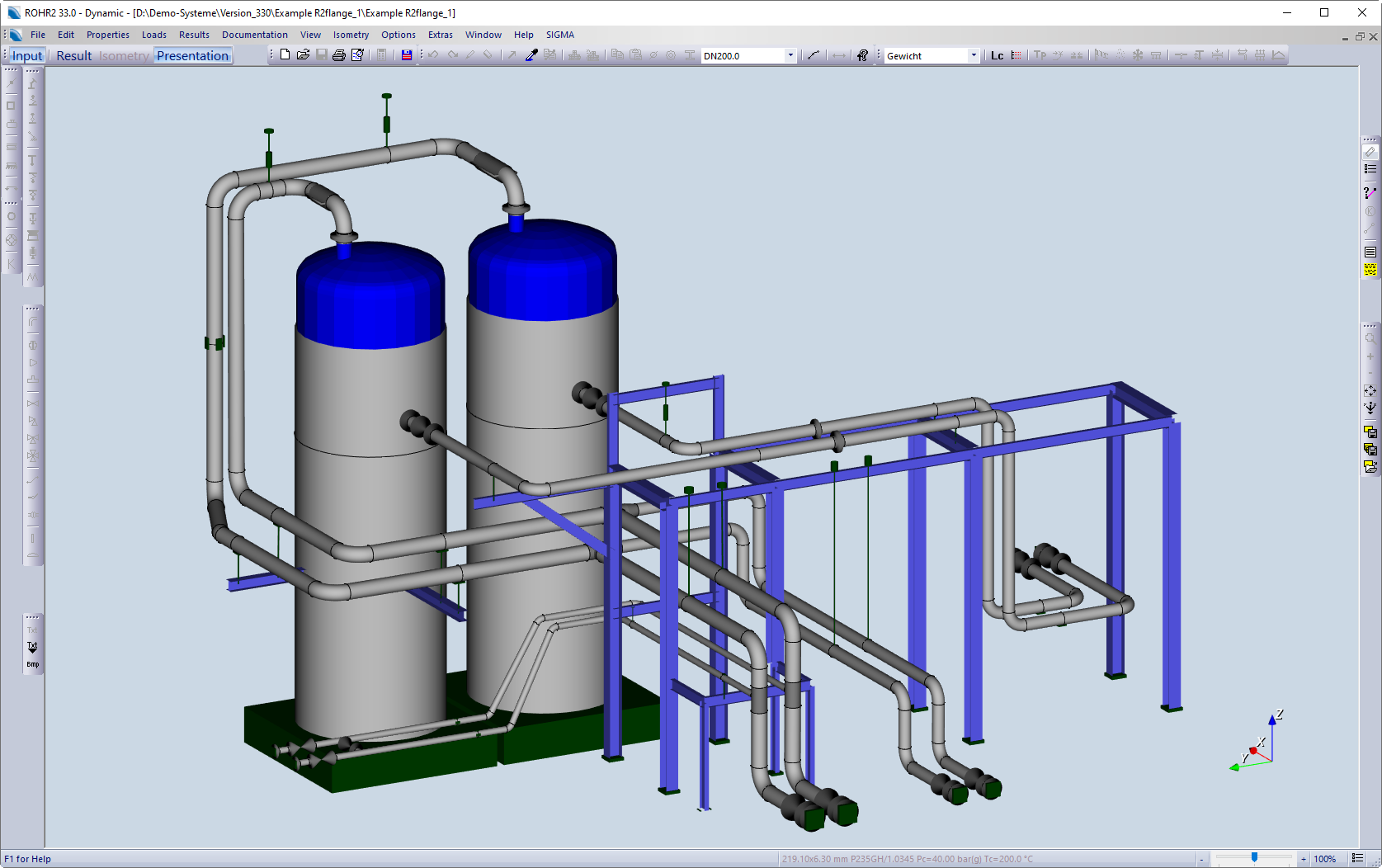

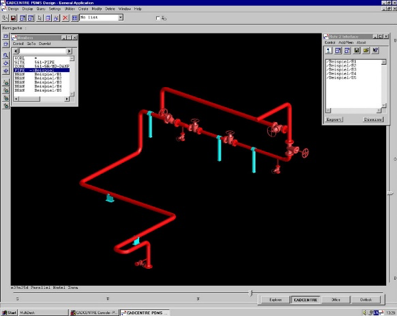

ROHR2 is the leading European Software for Pipe Stress Analysis, a standard tool for pipe static and structural framework analysis.

Tasks of ROHR2

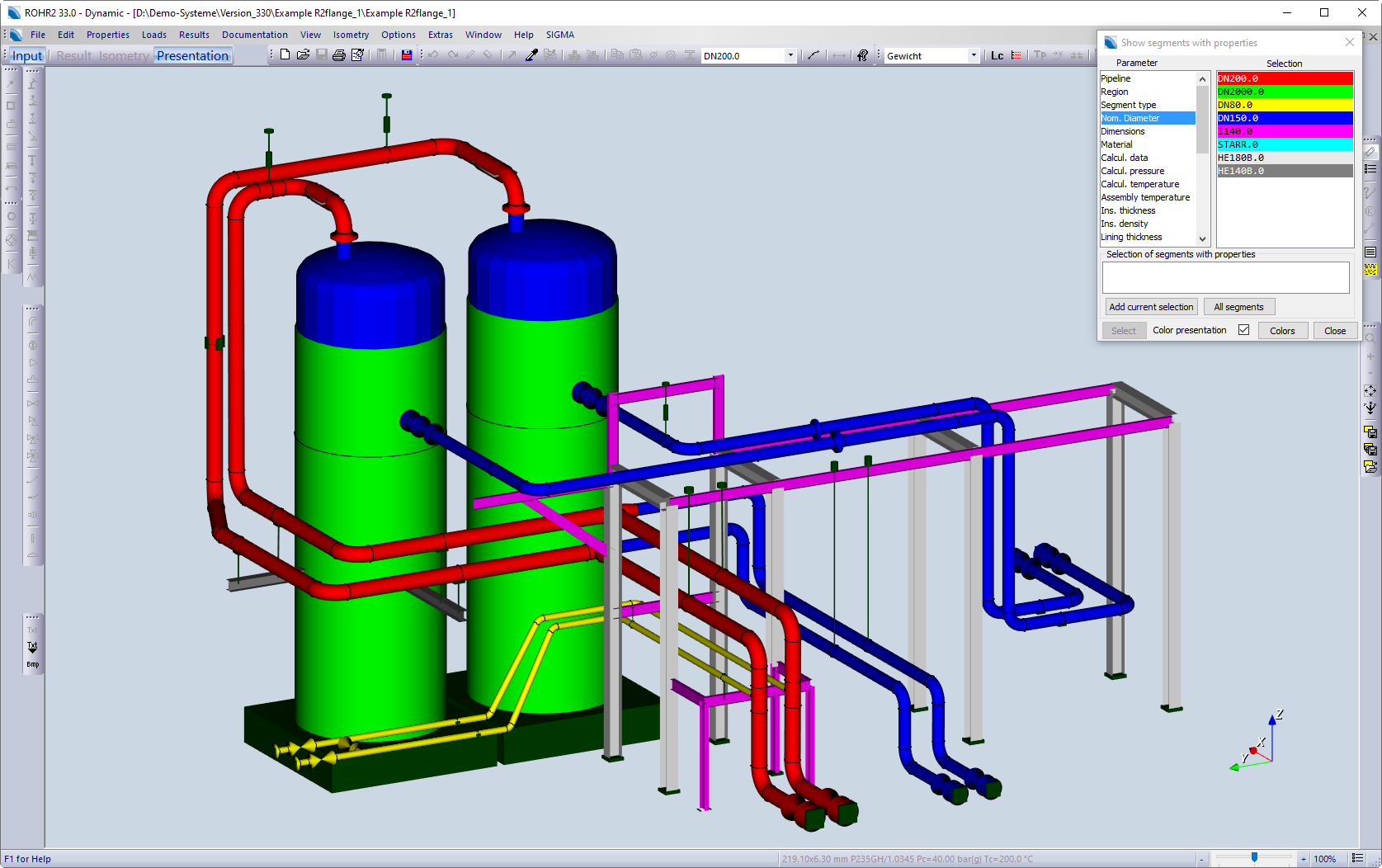

The main tasks of ROHR2 are component analysis, construction and structural analysis of complex piping systems and associated steel structures.

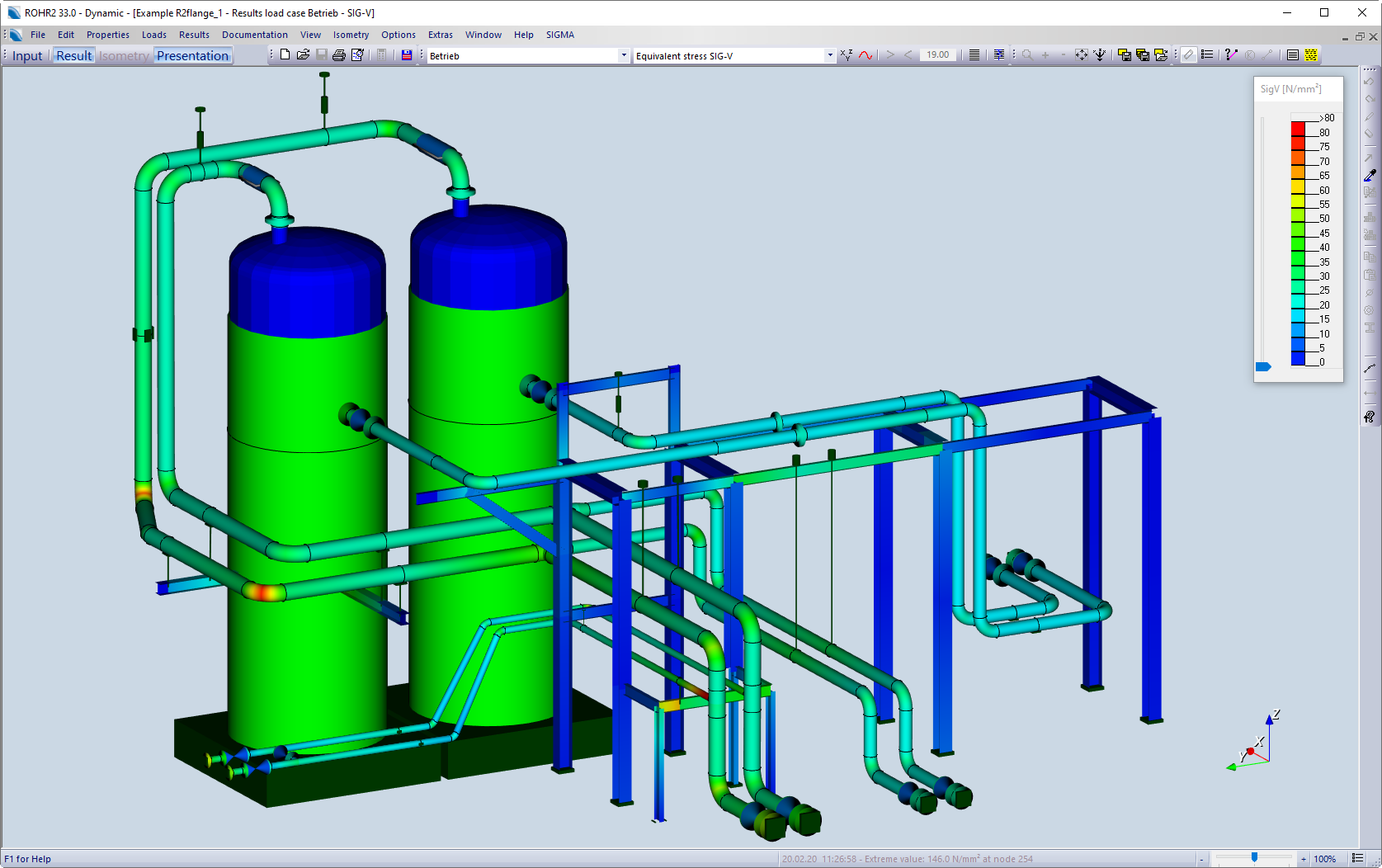

Stress analyses of pipe components can be done by in accordance with a variety of specifications like ASME, EN, ISO14692, KTA, CODETI, RCCM or DVS 2210.

ROHR2 creates the load case superposition and the equations automatically according to the selected stress specification.

ROHR2 compares existing and allowable stresses. The results will be documented in lists and graphical presentations. The range of applications is completed by internal pressure analysis and flange and nozzle calculation modules.

The static analysis includes the analysis of any loads and load combinations according to first and second order theory for linear and nonlinear boun¬dary conditions (friction, gap of supports, support uplift) and coupling conditions (nonlinear regulation powers of expansion joints).

The dynamic analysis includes the calculation of eigen values and mode shapes and their analysis by means of different modal response methods or direct integration method (e.g. analysis of fluid hammer forces).

The earthquake analysis is based on the Method of Time – History.

An efficient superposition module enables a versatile selection and combination of static and dynamic results as well as the generation of extreme values for loads on supports, components and nozzles.

Program system ROHR2 – Optional modules and interfaces.

The program system ROHR2 is equipped by a range of additional features enhancing the engineer’s daily job, as there are FEM analysis (ROHR2fesu), isometric capabilities (ROHR2ISO) and a wide range of interfaces covering the leading CAD/CAE systems.

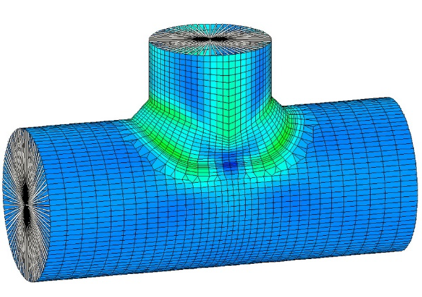

ROHR2fesu

FE analysis of substructures in ROHR2

ROHR2iso

Piping isometries in ROHR2

ROHR2 Interfaces

Communication with CAD/CAE software:

AVEVA PDMS, CADISON, INTERGRAPH PDS/ SMARTPLANT, MPDS4, HICADnext, CII, SINETZ, AUTOCAD via ALIAS PCF/ISOGEN, AUTOPLANT and others

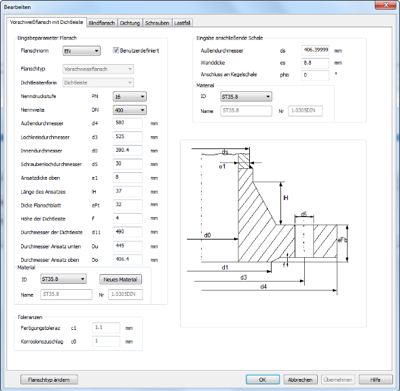

ROHR2flange

Calculation of standard flanges acc. to EN 1591-1, ASME VIII, Div.1

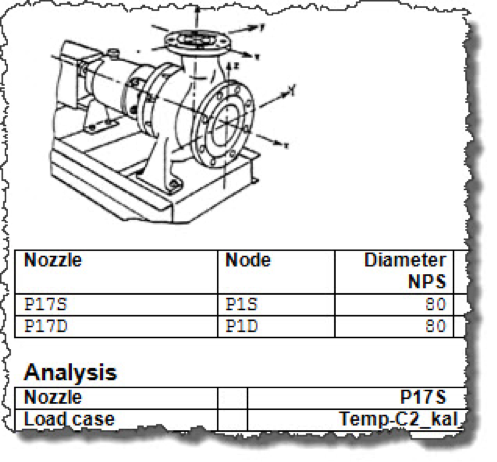

ROHR2nozzle

Analysis of nozzles in piping systems according to API 610, 617, 661, NEMA SM23, DIN EN ISO 5199, 9905, 10437 and others

Internal pressure analysis

Internal pressure analysis of piping components in ROHR2.

For presentation and trials contact:

Syed Rizvi

416-884-1982

srizvi@dconsulthink.com